Mr. B worked as a machine operator at a factory in Monroe, Georgia that made paper bags. One day he was feeding paper into the machine when his hand got caught in the machine and pulled into two metal rollers. He suffered a degloving injury to his left hand that required multiple surgeries and left him unable to fully use his left hand. Michael investigated the accident and determined the machine was not properly guarded and violated safety and machine guarding standards. He filed a lawsuit in federal court against the company that manufactured the machine, defeated motions to dismiss the case and secured a confidential settlement for Mr. B.

Machine Violated Safety Standards

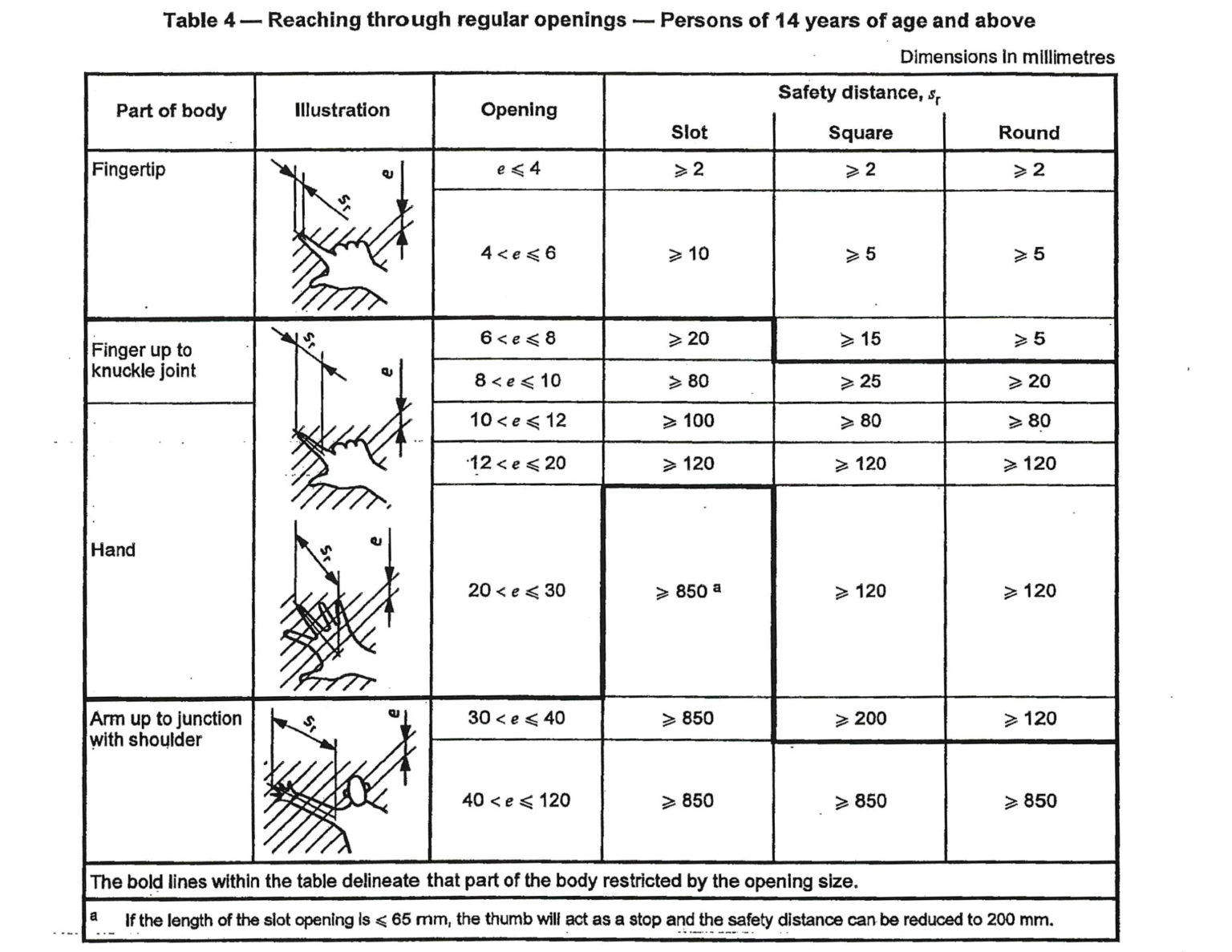

The purpose of machine guarding is to protect people from the parts of the machine that can cause injury. Machine guarding safety standards are set by OSHA and organizations such as ISO and ANSI. In this case, the company that made the machine certified that it complied with ISO 13857, which is an international safety and machine guarding standard.

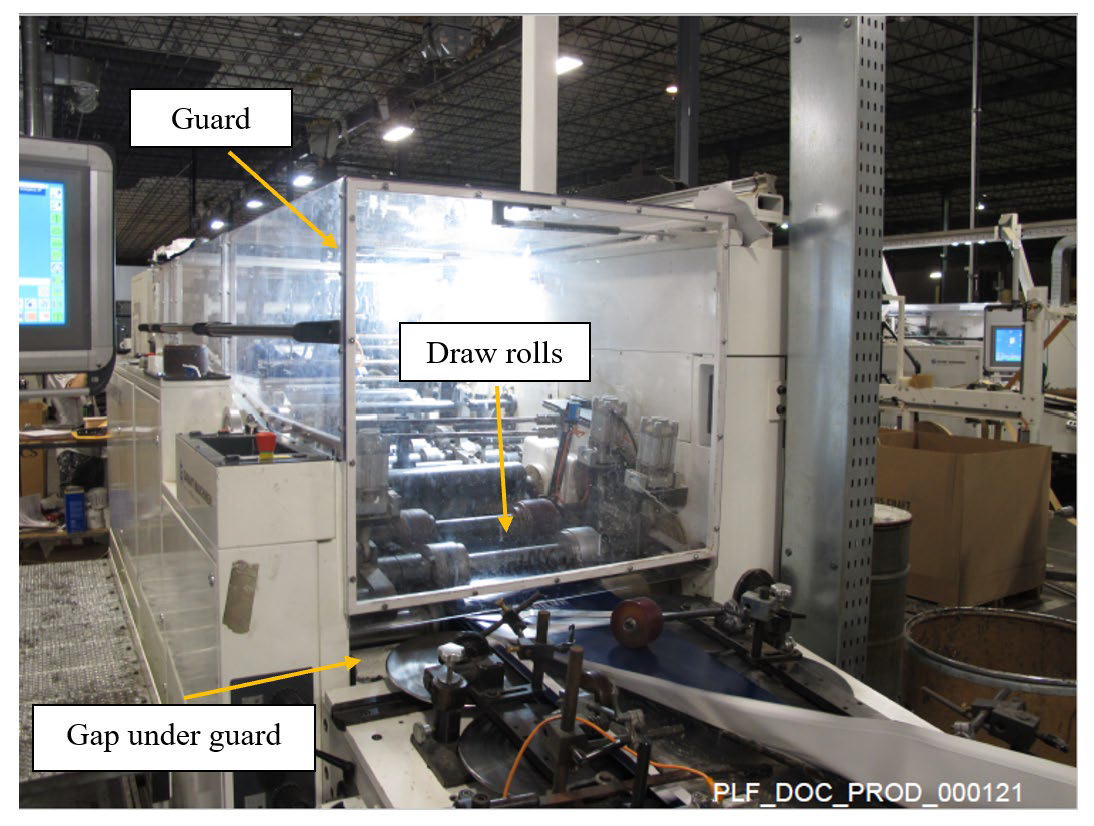

Below is a picture of the machine that injured Mr. B.

As you can see, the machine had a plexiglass guard covering the rollers that was intended to prevent workers’ hands and arms from getting injured by the rollers. When a machine has a guard like this, ISO 13857, table 4 sets specific safety distances that the guard must be from the hazard (in this case, the rollers) to prevent injury.

We retained a professional engineer with a Ph.D in mechanical engineering as an expert witness. He inspected the machine and measured the size of the guard opening at 52 millimeters. Given this, table 4 required a safety distance to the metal rollers of at least 850 millimeters. However, our expert measured the distance to the rollers at only 214 millimeters, proving that the machine violated the safety standard.

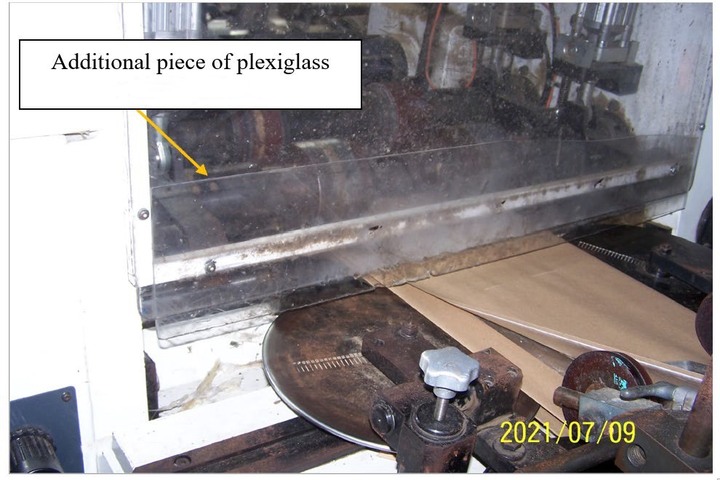

If the manufacturer had simply extended the guard further down, which would have reduced the size of the opening, the machine would have complied with the safety standards and prevented Mr. B’s injury.

And in fact, that’s exactly what the plant where Mr. B worked did. During our inspection of the plant and machine, we found that plant employees had added an additional section of plexiglass to the other machines at the plant, essentially proving that the guard was unsafe.

The Operations to Fix Mr. B’s Hand

Mr. B was life-flighted to Grady Hospital in Atlanta. He had to undergo four operations to try to repair his hand. The surgeries involved multiple skin grafts and a debridement procedure where they cleaned the wound and removed any dead or seriously damaged tissue. Despite the surgeon’s best efforts, Mr. B’s hand will never be the same. According to Mr. B’s surgeon, his left hand is now a “helper” hand and he will continue t

The Impact of the Injury on Mr. B’s Quality of Life

Mr. B is left-handed and this injury has had a significant impact on him and his life. He has been forced to learn to do almost every activity of daily life with his right hand instead of his left. He cannot write with his left hand and is trying to learn to write with his right hand. He cannot use his left hand for typing and has had to learn to type and text with his right hand instead, which he does slowly and often inaccurately. He cannot use his left hand for activities like brushing his teeth and using a fork and spoon. Because he cannot hold both a knife and a fork, he can no longer cut his own food and has to have help from his wife or children. He has a hard time buttoning his shirts and pants and doing so takes much longer than it used to. He has to ask his wife or children for help tying his shoes or has to wear slip-on shoes. He cannot do even a simple activity like peeling an orange and now has to ask for help with it.

Mr. B used to do all the yard work and handy work around the house. He can no longer use a hammer or screwdriver because he cannot hold them with his left hand and is not yet able to use them with his right hand. He cannot use a lawnmower to cut the grass because the vibrations from it hurt his left hand. He cannot use a rake because he cannot hold the rake with both hands. He would do work around the house like hanging sheetrock and plumbing but is now no longer able to do so. He used to work on his family’s car and change the oil and brakes but cannot do so any longer.

Mr. B’s left hand is now very sensitive to pain and cold. If something accidentally or inadvertently touches his left hand it can cause significant pain. His left hand often hurts in cold weather and he cannot go outside in cold temperatures unless his hand is fully covered. In the summer, when he and his family go to the pool, the cold water hurts his hand and he is reluctant to get in the water and play with his children.

Mr. B has three children, aged 25, 14 and 12. He used to play basketball and roughhouse with his 14 and 12-year-old boys but can no longer do so because he cannot dribble or shoot with his left hand and is also worried about one of the boys or the basketball accidentally hitting his left hand, which would be very painful.

What We Did To Help

We filed a lawsuit against the company that manufactured the machine. Since the company was based in Germany, we had to file the lawsuit in federal court and serve them with the lawsuit under The Hague Convention. We took depositions of multiple employees of the company, using Zoom to depose them since the employees were in Germany. We obtained a report from Mr. B’s surgeon explaining the surgeries he performed and the limitations that Mr. B now has with his his hand. The surgeon wrote that Mr. B’s dominant hand was now essentially a “helper hand” and that the loss of use of his dominant hand was “immeasureable.” The surgeon further explained that Mr. B is likely to need additional surgery to try to improve the function of his hand. We defeated motions filed by the defendant asking the Court to rule in their favor. We were then able to secure a confidential settlement for Mr. B that fairly compensated him for his injuries.

We’re glad we could help Mr. B and wish him the best in his recovery.